Переходы по ТУ 1468-009-01394395-03 предназначены для магистральных нефтегазопроводов, проектируемых и сооружаемых по СНиП 2.05.06-85* и СНиП III-42-80* на давление до 10 МПа и промысловых трубопроводов по СП 34-116-97 на давление до 16 МПа, транспортирующих подготовленные среды при температурах от 233 К (минус 40 0С) до 423 К (150 0С).

|

DN

|

D – D1, мм

|

Т – Т1, мм

|

Масса, кг

|

Тип

|

РN (условное давление), МПа

|

|

марка стали

|

|

К 42

|

К 48

|

К 50

|

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

40

|

45 - 32

|

4,0 - 4,0

|

0,1

|

К

|

16

|

|

|

|

50

|

57 - 38

|

4,0 - 4,0

|

0,19

|

К, Э

|

16

|

|

|

|

50

|

57 - 45

|

4,0 - 4,0

|

0,28

|

К, Э

|

16

|

|

|

|

65

|

76 - 45

|

4,0 - 4,0

|

0,39

|

К

|

16

|

|

|

|

65

|

76 - 57

|

4,0 - 4,0

|

0,43

|

К, Э

|

16

|

|

|

|

80

|

89 - 45

|

4,0 - 4,0

|

0,47

|

К

|

15

|

16

|

|

|

80

|

89 - 45

|

5,0 - 4,0

|

0,57

|

К

|

16

|

|

|

|

80

|

89 - 57

|

4,0 - 4,0

|

0,51

|

К, Э

|

15

|

16

|

|

|

80

|

89 - 57

|

5,0 - 4,0

|

0,63

|

К, Э

|

16

|

|

|

|

80

|

89 - 76

|

4,0 - 4,0

|

0,9

|

К, Э

|

15

|

16

|

|

|

80

|

89 - 76

|

5,0 - 5,0

|

0,72

|

К, Э

|

16

|

|

|

|

100

|

108 - 57

|

4,0 - 4,0

|

0,62

|

К

|

12

|

12

|

15

|

|

100

|

108 - 57

|

5,0 - 4,0

|

0,76

|

К

|

16

|

|

|

|

100

|

108 - 76

|

4,0 - 4,0

|

0,69

|

К

|

12

|

12

|

15

|

|

100

|

108 - 76

|

5,0 - 4,0

|

0,86

|

К

|

16

|

|

|

|

100

|

108 - 89

|

4,0 - 4,0

|

0,75

|

К, Э

|

12

|

12

|

15

|

|

100

|

108 - 89

|

5,0 - 5,0

|

0,92

|

К, Э

|

16

|

|

|

|

125

|

133 - 76

|

4,0 - 4,0

|

0,90

|

К

|

10

|

10

|

12

|

|

125

|

133 - 76

|

5,0 - 4,0

|

1,11

|

К

|

12

|

12

|

15

|

|

125

|

133 - 76

|

6,0 - 4,0

|

1,32

|

К

|

15

|

16

|

|

|

125

|

133 - 76

|

7,0 - 4,0

|

1,52

|

К

|

16

|

|

|

|

125

|

133 - 89

|

4,0 - 4,0

|

1,06

|

К

|

10

|

10

|

12

|

|

125

|

133 - 89

|

5,0 - 4,0

|

1,31

|

К

|

12

|

12

|

15

|

|

125

|

133 - 89

|

6,0 - 5,0

|

1,55

|

К

|

15

|

16

|

|

|

125

|

133 - 89

|

7,0 - 5,0

|

1,80

|

К

|

16

|

|

|

|

125

|

133 - 108

|

4,0 - 4,0

|

1,15

|

К, Э

|

10

|

10

|

12

|

|

125

|

133 - 108

|

5,0 - 5,0

|

1,42

|

К, Э

|

12

|

12

|

15

|

|

125

|

133 - 108

|

6,0 - 5,0

|

1,69

|

К, Э

|

15

|

16

|

|

|

125

|

133 - 108

|

7,0 - 6,0

|

1,96

|

К, Э

|

16

|

|

|

|

150

|

159 - 89

|

4,0 - 4,0

|

1,54

|

К

|

8,5

|

8,5

|

10

|

|

150

|

159 - 89

|

5,0 - 4,0

|

1,91

|

К

|

10

|

12

|

12

|

|

150

|

159 - 89

|

6,0 - 4,0

|

2,27

|

К

|

12

|

12

|

15

|

|

150

|

159 - 89

|

7,0 - 4,0

|

2,63

|

К

|

15

|

16

|

|

|

150

|

159 - 89

|

8,0 - 5,0

|

2,98

|

К

|

16

|

|

|

|

150

|

159 - 108

|

4,0 - 4,0

|

1,66

|

К, Э

|

8,5

|

8,5

|

10

|

|

150

|

159 - 108

|

5,0 - 4,0

|

2,06

|

К, Э

|

10

|

12

|

12

|

|

150

|

159 - 108

|

6,0 - 5,0

|

2,45

|

К, Э

|

12

|

12

|

15

|

|

150

|

159 - 108

|

7,0 - 5,0

|

2,84

|

К, Э

|

15

|

16

|

|

|

150

|

159 - 108

|

8,0 - 6,0

|

3,22

|

К, Э

|

16

|

|

|

|

150

|

159 - 114

|

4,0 - 4,0

|

1,70

|

К

|

8,5

|

8,5

|

10

|

|

150

|

159 - 114

|

5,0 - 4,0

|

2,11

|

К

|

10

|

12

|

12

|

|

150

|

159 - 114

|

6,0 - 5,0

|

2,51

|

К

|

12

|

12

|

15

|

|

150

|

159 - 114

|

7,0 - 6,0

|

2,91

|

К

|

15

|

16

|

|

|

150

|

159 - 114

|

8,0 - 6,0

|

3,30

|

К

|

16

|

|

|

|

150

|

159 - 133

|

4,0 - 4,0

|

1,82

|

К

|

8,5

|

8,5

|

10

|

|

150

|

159 - 133

|

5,0 - 5,0

|

2,26

|

К

|

10

|

12

|

12

|

|

150

|

159 - 133

|

6,0 - 6,0

|

2,69

|

К

|

12

|

12

|

15

|

|

150

|

159 - 133

|

7,0 – 6,0

|

3,12

|

К

|

15

|

16

|

|

|

150

|

159 - 133

|

8,0 - 7,0

|

3,54

|

К

|

16

|

|

|

|

200

|

219 - 108

|

5,0 - 4,0

|

1,86

|

К

|

7,5

|

8,5

|

8,5

|

|

200

|

219 - 108

|

6,0 - 4,0

|

2,21

|

К

|

8,5

|

10

|

10

|

|

200

|

219 - 108

|

7,0 - 4,0

|

2,57

|

К

|

10

|

12

|

12

|

|

200

|

219 - 108

|

8,0 - 4,0

|

2,91

|

К

|

12

|

12

|

15

|

|

200

|

219 - 108

|

9,0 - 5,0

|

3,26

|

К

|

12

|

16

|

|

|

200

|

219 - 108

|

10,0 - 5,0

|

3,60

|

К

|

16

|

|

|

|

200

|

219 - 114

|

5,0 - 4,0

|

1,89

|

К

|

7,5

|

8,5

|

8,5

|

|

200

|

219 - 114

|

6,0 - 4,0

|

2,26

|

К

|

8,5

|

10

|

10

|

|

200

|

219 - 114

|

7,0 - 4,0

|

2,62

|

К

|

10

|

12

|

12

|

|

200

|

219 - 114

|

8,0 - 5,0

|

2,97

|

К

|

12

|

12

|

15

|

|

200

|

219 - 114

|

9,0 - 5,0

|

3,32

|

К

|

12

|

16

|

|

|

200

|

219 - 114

|

10,0 - 6,0

|

3,67

|

К

|

16

|

|

|

|

200

|

219 - 133

|

5,0 - 4,0

|

2,95

|

К

|

7,5

|

8,5

|

8,5

|

|

200

|

219 - 133

|

6,0 - 4,0

|

3,52

|

К

|

8,5

|

10

|

10

|

|

200

|

219 - 133

|

7,0 - 5,0

|

4,08

|

К

|

10

|

12

|

12

|

|

200

|

219 - 133

|

8,0 - 5,0

|

4,64

|

К

|

12

|

12

|

15

|

|

200

|

219 - 133

|

9,0 - 6,0

|

5,19

|

К

|

12

|

16

|

|

|

200

|

219 - 133

|

10,0 - 7,0

|

5,73

|

К

|

16

|

|

|

|

200

|

219 - 159

|

5,0 - 4,0

|

3,18

|

К, Э

|

7,5

|

8,5

|

8,5

|

|

200

|

219 - 159

|

6,0 - 5,0

|

3,79

|

К, Э

|

8,5

|

10

|

10

|

|

200

|

219 - 159

|

7,0 - 6,0

|

4,40

|

К, Э

|

10

|

12

|

12

|

|

200

|

219 - 159

|

8,0 - 6,0

|

5,00

|

К, Э

|

12

|

12

|

15

|

|

200

|

219 - 159

|

9,0 - 7,0

|

5,59

|

К, Э

|

12

|

16

|

|

|

200

|

219 - 159

|

10,0 - 8,0

|

6,18

|

К, Э

|

16

|

|

|

|

250

|

273 - 159

|

5,0 - 4,0

|

4,68

|

К

|

5,6

|

6,3

|

6,3

|

|

250

|

273 - 159

|

6,0 - 4,0

|

5,59

|

К

|

6,3

|

7,5

|

8,5

|

|

250

|

273 - 159

|

7,0 - 5,0

|

6,49

|

К

|

8,5

|

8,5

|

10

|

|

250

|

273 - 159

|

8,0 - 5,0

|

7,39

|

К

|

8,5

|

10

|

10

|

|

250

|

273 - 159

|

9,0 - 6,0

|

8,27

|

К

|

10

|

12

|

12

|

|

250

|

273 - 159

|

10,0 - 6,0

|

9,14

|

К

|

12

|

12

|

15

|

|

250

|

273 - 159

|

11,0 - 7,0

|

10,01

|

К

|

12

|

16

|

|

|

250

|

273 - 159

|

12,0 - 7,0

|

10,87

|

К

|

15

|

16

|

|

|

250

|

273 - 159

|

14,0 - 9,0

|

12,55

|

К

|

16

|

|

|

|

250

|

273 - 219

|

5,0 - 5,0

|

5,35

|

К, Э

|

5,6

|

6,3

|

6,3

|

|

250

|

273 - 219

|

6,0 - 5,0

|

6,39

|

К, Э

|

6,3

|

7,5

|

8,5

|

|

250

|

273 - 219

|

7,0 - 6,0

|

7,43

|

К, Э

|

8,5

|

8,5

|

10

|

|

250

|

273 - 219

|

8,0 - 7,0

|

8,45

|

К, Э

|

8,5

|

10

|

10

|

|

250

|

273 - 219

|

9,0 - 8,0

|

9,47

|

К, Э

|

10

|

12

|

12

|

|

250

|

273 - 219

|

10,0 - 9,0

|

10,48

|

К, Э

|

12

|

12

|

15

|

|

250

|

273 - 219

|

11,0 - 9,0

|

11,47

|

К, Э

|

12

|

16

|

|

|

250

|

273 - 219

|

12,0 - 10,0

|

12,46

|

К, Э

|

15

|

16

|

|

|

250

|

273 - 219

|

14,0 - 12,0

|

14,42

|

К, Э

|

16

|

|

|

|

300

|

325 - 219

|

5,0 - 4,0

|

5,93

|

К

|

4

|

5,6

|

5,6

|

|

300

|

325 - 219

|

6,0 - 5,0

|

7,08

|

К

|

5,6

|

6,3

|

6,3

|

|

300

|

325 - 219

|

7,0 - 5,0

|

8,23

|

К

|

6,3

|

7,5

|

7,5

|

|

300

|

325 - 219

|

8,0 - 6,0

|

9,38

|

К

|

7,5

|

8,5

|

8,5

|

|

300

|

325 - 219

|

9,0 - 7,0

|

10,51

|

К

|

8,5

|

10

|

10

|

|

300

|

325 - 219

|

10,0 - 7,0

|

11,63

|

К

|

10

|

12

|

12

|

|

300

|

325 - 219

|

11,0 - 8,0

|

12,74

|

К

|

10

|

12

|

12

|

|

300

|

325 - 219

|

12,0 - 9,0

|

13,85

|

К

|

12

|

12

|

15

|

|

300

|

325 - 219

|

14,0 - 10,0

|

16,03

|

К

|

15

|

16

|

|

|

300

|

325 - 273

|

5,0 - 5,0

|

6,53

|

К, Э

|

4

|

5,6

|

5,6

|

|

300

|

325 - 273

|

6,0 - 6,0

|

7,80

|

К, Э

|

5,6

|

6,3

|

6,3

|

|

300

|

325 - 273

|

7,0 - 6,0

|

9,07

|

К, Э

|

6,3

|

7,5

|

7,5

|

|

300

|

325 - 273

|

8,0 - 7,0

|

10,33

|

К, Э

|

7,5

|

8,5

|

8,5

|

|

300

|

325 - 273

|

9,0 - 8,0

|

11,59

|

К, Э

|

8,5

|

10

|

10

|

|

300

|

325 - 273

|

10,0 - 9,0

|

12,83

|

К, Э

|

10

|

12

|

12

|

|

300

|

325 - 273

|

11,0 - 10,0

|

14,06

|

К, Э

|

10

|

12

|

12

|

|

300

|

325 - 273

|

12,0 - 11,0

|

15,29

|

К, Э

|

12

|

12

|

15

|

|

300

|

325 - 273

|

14,0 - 12,0

|

17,71

|

К, Э

|

15

|

16

|

|

|

350

|

377 - 273

|

6,0 - 5,0

|

10,32

|

К

|

4

|

5,6

|

6,3

|

|

350

|

377 - 273

|

7,0 - 6,0

|

12,00

|

К

|

5,6

|

6,3

|

6,3

|

|

350

|

377 - 273

|

8,0 - 6,0

|

13,67

|

К

|

6,3

|

7,5

|

8,5

|

|

350

|

377 - 273

|

9,0 - 7,0

|

15,33

|

К

|

7,5

|

8,5

|

8,5

|

|

350

|

377 - 273

|

10,0 - 8,0

|

16,96

|

К

|

8,5

|

10

|

10

|

|

350

|

377 - 273

|

11,0 - 9,0

|

18,62

|

К

|

10

|

10

|

10

|

|

350

|

377 - 273

|

12,0 - 9,0

|

20,25

|

К

|

10

|

12

|

12

|

|

350

|

377 - 273

|

14,0 - 11,0

|

23,47

|

К

|

12

|

12

|

15

|

|

350

|

377 - 325

|

6,0 - 6,0

|

11,17

|

К, Э

|

4

|

5,6

|

6,3

|

|

350

|

377 - 325

|

7,0 - 7,0

|

12,99

|

К, Э

|

5,6

|

6,3

|

6,3

|

|

350

|

377 - 325

|

8,0 - 7,0

|

14,80

|

К, Э

|

6,3

|

7,5

|

8,5

|

|

350

|

377 - 325

|

9,0 - 8,0

|

16,60

|

К, Э

|

7,5

|

8,5

|

8,5

|

|

350

|

377 - 325

|

10,0 - 9,0

|

18,39

|

К, Э

|

8,5

|

10

|

10

|

|

350

|

377 - 325

|

11,0 - 10,0

|

20,17

|

К, Э

|

10

|

10

|

10

|

|

350

|

377 - 325

|

12,0 - 11,0

|

21,94

|

К, Э

|

10

|

12

|

12

|

|

350

|

377 - 325

|

14,0 - 14,0

|

25,45

|

К, Э

|

12

|

12

|

15

|

|

400

|

426 - 325

|

6,0 - 5,0

|

12,03

|

К

|

4

|

4

|

4

|

|

400

|

426 - 325

|

7,0 - 6,0

|

14,00

|

К

|

4

|

5,6

|

6,3

|

|

400

|

426 - 325

|

8,0 - 7,0

|

15,95

|

К

|

5,6

|

6,3

|

6,3

|

|

400

|

426 - 325

|

9,0 - 7,0

|

17,90

|

К

|

6,3

|

7,5

|

7,5

|

|

400

|

426 - 325

|

10,0 - 8,0

|

19,83

|

К

|

7,5

|

8,5

|

8,5

|

|

400

|

426 - 325

|

11,0 - 9,0

|

21,75

|

К

|

8,5

|

8,5

|

10

|

|

400

|

426 - 325

|

12,0 - 10,0

|

23,67

|

К

|

8,5

|

10

|

10

|

|

400

|

426 - 325

|

14,0 - 11,0

|

27,46

|

К

|

10

|

12

|

12

|

|

400

|

426 - 377

|

6,0 - 6,0

|

12,81

|

К, Э

|

4

|

4

|

4

|

|

400

|

426 - 377

|

7,0 - 7,0

|

14,91

|

К, Э

|

4

|

5,6

|

6,3

|

|

400

|

426 - 377

|

8,0 - 8,0

|

16,99

|

К, Э

|

5,6

|

6,3

|

6,3

|

|

400

|

426 - 377

|

9,0 - 8,0

|

19,07

|

К, Э

|

6,3

|

7,5

|

7,5

|

|

400

|

426 - 377

|

10,0 - 9,0

|

21,13

|

К, Э

|

7,5

|

8,5

|

8,5

|

|

400

|

426 - 377

|

11,0 - 10,0

|

23,19

|

К, Э

|

8,5

|

8,5

|

10

|

|

400

|

426 - 377

|

12,0 - 11,0

|

25,23

|

К, Э

|

8,5

|

10

|

10

|

|

400

|

426 - 377

|

14,0 - 14,0

|

29,28

|

К, Э

|

10

|

12

|

12

|

|

500

|

530 - 426

|

7,0 - 6,0

|

24,39

|

К

|

4

|

4

|

4

|

|

500

|

530 - 426

|

8,0 - 7,0

|

27,82

|

К

|

4

|

5,6

|

5,6

|

|

500

|

530 - 426

|

9,0 - 8,0

|

31,23

|

К

|

5,6

|

6,3

|

6,3

|

|

500

|

530 - 426

|

10,0 - 9,0

|

34,62

|

К

|

5,6

|

6,3

|

6,3

|

|

500

|

530 - 426

|

11,0 - 9,0

|

38,01

|

К

|

6,3

|

7,5

|

7,5

|

|

500

|

530 - 426

|

12,0 - 10,0

|

41,37

|

К

|

7,5

|

8,5

|

8,5

|

|

500

|

530 - 426

|

14,0 - 12,0

|

48,06

|

К

|

8,5

|

10

|

10

|

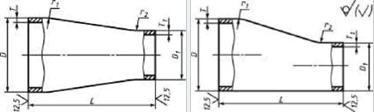

Пример условного обозначения:

Переход концентрический с наружными диаметрами на торцах 426 и 377 мм, толщинами стенки присоединяемых труб соответственно 10 и 8 мм, на давление 7,5 МПа, из стали 20 при коэффициенте условий работы 0,75, исполнение У:

Переход К 426(10) – 377(8) – 7,5 – 0,75 – У ТУ 1468-009-01394395-03;

То же, эксцентрический:

Переход Э 426(10) – 377(8) – 7,5 – 0,75 – У ТУ 1468-009-01394395-03;

Тоже, из стали 09Г2С:

Переход Э 426(10) – 377(8) – 7,5 – 0,75 – 09Г2С - У ТУ 1468-009-01394395-03.

|